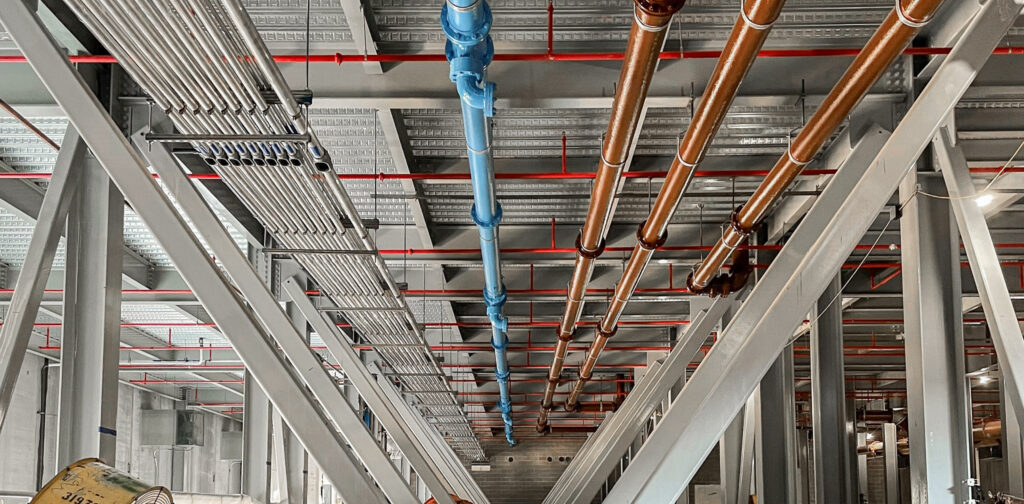

Process Piping & High Purity Solutions for Construction Projects

Delivering ultra purity and high purity process piping solutions with precision fabrication, expert installation, and strict code compliance for semiconductor, biotech, power generation, and clean manufacturing facilities

Process Piping Design, Fabrication & Installation Services

We specialize in the design, manufacturing, and installation of gas delivery systems and related components, supporting gas purity levels ranging from industrial grade to ultra-high purity.

Design

Our high-purity piping process is designed to meet ASME B31.1 and B31.3 standards, ensuring reliable performance in both power and critical process applications requiring strict safety and cleanliness.

Manufacturing

Our manufacturing process follows high-quality standards, including a 10% quality control inspection on all welds. We also apply the 5S lean methodology to maintain clean, organized, and efficient workspaces.

Installation

We employ experienced orbital welders, fitters, and specialty foremen who ensure precise, high-quality piping installations for critical process piping systems.

Delivering high purity piping , process piping solutions, and gas distribution systems

- With decades of experience and deep roots in the Houston market, our team is equipped to handle complex mechanical scopes for new construction, design-build, retrofits, and renovations.

- We utilize cost-effective, high-quality materials and components to ensure durable and high-performance solutions. All systems are designed and installed in accordance with the latest applicable codes

- We proudly serve a range of industries including semiconductor, fuel power generation, petrochemical, and other heavy industrial markets.

Process

Construction & Installation Process

We don’t just deliver systems—we deliver success through structured, expert-led project execution. Our process piping services are supported by:

Staff Augmentation

Skilled manpower, craft training, and technical support

Project Management

Dedicated supervisors, managers, and full oversight

Skilled Craft Personnel

Qualified manual and orbital welders, Certified welders inspectors (CWI), Site safety specialists, QA/QC teams, welding engineers

Process

Specialty Welding Solutions

Kilgore offers both manual and orbital welding services, with deep expertise in maintenance, life extension, specialty engineering, and new construction applications.

Our specialty welding services are performed to the highest standards, with all processes designed to meet ASME B31.1 and B31.3 code requirements. From orbital to manual welding, our certified welders deliver precision and reliability for complex process piping applications.

Manual Tube Welding Methods

- Shielded Metal Arc Welding (SMAW)

- Gas Tungsten Arc Welding (GTAW)

- Flux-Cored Arc Welding (FCAW)

- Gas Metal Arc Welding (GMAW)

Machine / Orbital Tube and Pipe Welding

- Computer-controlled orbital welding

- Precision welds for high purity systems

Welding Certifications

- American Welding Society (AWS) certified

- ASME certified

Custom Design

Tailored solutions that meet gas distribution specific purity requirements and operational needs.

Fabrication

High QC process and orbital welding techniques for contaminant-free assemblies.

Installation

Certified technicians ensure seamless integration with existing infrastructure, minimizing downtime.

Process

Gas Distribution Systems

We design and install gas distribution systems at all scales—from compact units to plant-wide infrastructure—for gases of all purity levels.

Our service extends beyond piping—we provide turnkey solutions that integrate design, fabrication, installation, and validation of gas delivery systems tailored to ultra-high purity (UHP) and industrial-grade applications.

- Factory distribution systems

- Gas pad design and integration

- Source panels (gas and multi-gas)

- Point-of-use regulation systems

- Stainless steel applications

- Ultra-high purity (UHP) and industrial grade solutions

- Bulk gas integration systems:

- Liquid source systems

- Tube trailers

- Tube pad connections

- Switch-over systems

- Expansion-ready designs

Industry-Specific Process Piping Solutions

At Kilgore Industries, we specialize in delivering customized process piping and gas distribution systems that meet the stringent demands of diverse industries.

We provide sanitary piping systems that uphold the highest hygiene standards essential for food and beverage production.

Utilizing 316L stainless steel, our designs facilitate Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes, ensuring contamination-free operations. Our services encompass:

Design & Installation: Tailored layouts that optimize flow and cleanliness.

Material Selection: Use of FDA-compliant materials like 316L stainless steel.

Our high-purity piping solutions cater to the precise requirements of medical and laboratory environments.

Medical Gas Systems: Installation of systems for oxygen, nitrogen, and other critical gases.

Laboratory Gas Distribution: Safe and efficient delivery systems for various laboratory gases.

Compliance: Adherence to ASME B31.3 and NFPA 99 standards.

We design robust piping systems capable of handling aggressive chemicals and high-pressure processes.

Selection of appropriate materials like stainless steel based on chemical compatibility.

Our process piping solutions support the efficient and safe operation of power generation facilities.

Design and installation of piping systems that withstand high temperatures and pressures.

We offer specialized piping systems for the petrochemical industry, focusing on durability and safety.

Process Piping: Design of systems that handle various hydrocarbons and chemicals.

Material Selection: Use of materials like carbon steel and alloy steel suitable for petrochemical applications.

Design of delivery systems for specialty gases used in semiconductor manufacturing.

Ultra-High Purity (UHP) Piping: Installation of systems that prevent contamination in critical processes

Start Today

We can help with your specialized project needs.