Cooling towers are precision-engineered structures designed to dissipate excess heat through an advanced heat exchange process, ensuring efficient climate control and optimal system performance. By leveraging the principles of water evaporation and airflow, cooling towers effectively regulate temperatures in environments where traditional air-cooled systems may fall short.

Integrated into certain types of HVAC systems, these type of mechanical equipment play a crucial role in enhancing energy efficiency, reducing operational costs, and supporting sustainable building practices. Their ability to manage thermal loads makes them an essential solution for large-scale commercial, industrial, and institutional development projects.

Cooling towers are also integral to energy compliance, especially as industries work to reduce their carbon footprint in both process and comfort cooling applications. Their implementation enables the use of smaller, more efficient chillers, reducing the overall mechanical system footprint while optimizing space utilization. By enhancing energy efficiency and minimizing reliance on oversized mechanical equipment, cooling towers provide a more sustainable, cost-effective solution for modern HVAC systems.

What Is a Cooling Tower & How Does It Work?

A cooling tower is a specialized component that removes excess heat from a building’s HVAC system and releases it into the atmosphere. It functions by evaporating water and transferring heat energy from the facility, which lowers the overall temperature of the circulating water.

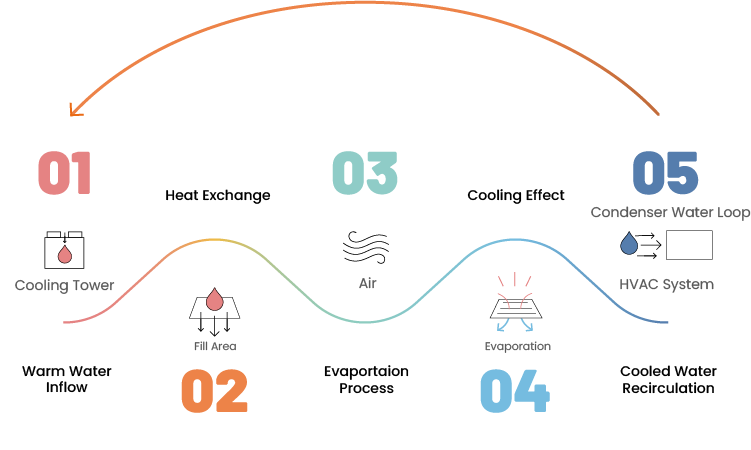

The cooling process follows these key steps:

This cooling tower process diagram visually explains the heat exchange and cooling cycle within an HVAC system. The diagram outlines five key steps.

This continuous cycle is essential for preventing overheating in large-scale mechanical systems and maintaining energy efficiency in buildings.

Warm Water Inflow: Entry from chillers, condensers, or industrial processes heated water from HVAC chillers, manufacturing equipment, or industrial processes enters the cooling tower through an inlet pipe. This water has absorbed excess heat from the system and needs to be cooled before recirculation. The temperature of incoming water typically ranges between 80°F to 120°F, depending on system demand.

Heat Exchange: Water is dispersed over the fill area Inside the cooling tower, the warm water is distributed evenly over the fill area—a structured surface designed to increase heat dissipation and improve cooling efficiency. Fill area types include splash fill (which breaks water into droplets) and film fill (which spreads water into thin layers for better heat transfer). This step enhances contact between water and air, maximizing the cooling effect.

Evaporation Process: Fans draw air through the system large induced draft or forced draft fans pull or push ambient air through the cooling tower. This airflow promotes evaporation, which is the key mechanism for cooling the water. As warm water interacts with cooler air, a portion of it evaporates, carrying away heat.

Cooling Effect: Evaporation removes heat, lowering water temperature as evaporation occurs, the remaining water cools down before being collected in the cold water basin. The cooling effect depends on factors such as ambient air temperature, relative humidity, and water flow rate. on average, these mechanical equipment can lower water temperatures by 10°F to 30°F, making it suitable for reuse in HVAC and industrial applications.

Cooled Water Recirculation: Returning to the HVAC System the cooled water is collected at the bottom of the tower and pumped back into the HVAC system, chillers, or industrial machinery. This cycle repeats continuously, ensuring that heat is efficiently removed from the system.

Key Components

Cooling towers contain several essential components that ensure proper equipment operation.

- Fill Area – Enhances the surface area for water distribution, improving heat dissipation.

- Fans & Motors – Drive airflow through the tower, aiding in heat exchange.

- Drift Eliminators – Reduce water loss by capturing droplets that escape with exhaust air.

- Water Distribution System – Ensures the spread of hot water over the fill area.

- Cold Water Basin – Collects and redistributes cooled water back into the system.

- Pumps & Nozzles – Regulate water flow for optimal cooling performance.

Each component plays a critical role in ensuring the mechanical efficiency of the cooling tower and preventing breakdowns.

Cooling Tower Sizes: How Large Are They & What Determines Their Dimensions?

Cooling towers vary in size depending on the HVAC system capacity and building requirements.

- Small commercial: can be as compact as 6–10 feet in height and handle smaller HVAC loads.

- Large industrial: can reach over 200 feet in height and accommodate massive heat loads for factories, data centers, and power plants.

The size of a cooling tower is determined by factors such as airflow rate, heat load, and water circulation needs.

How Long Do Cooling Towers Last?

The lifespan of a cooling tower depends on planned maintenance:

- Well-maintained can typically last between 15 to 25 years before they need major upgrades.

- Routine maintenance inspections & cleaning prevent buildup, rust, and efficiency loss.

How Many Types of Cooling Towers Exist?

There are several types of cooling towers, each designed for specific applications and mechanical construction needs:

- Natural Draft – Rely on natural air circulation instead of fans, often used in power plants.

- Forced Draft – Use high-powered fans to force air through the system, ideal for industrial applications.

- Induced Draft – Feature fans that pull air upward, increasing cooling efficiency.

- Crossflow – Water flows downward while air moves horizontally, allowing energy-efficient cooling.

- Counterflow – Air moves upward against the flow of descending water for high-efficiency heat rejection.

Most Common Types of Cooling Tower for Commercial and Industrial Buildings:

- General HVAC: Crossflow Cooling Towers

- High-efficiency cooling: Induced Draft Cooling Towers

- Limited space installations: Counterflow Cooling Towers

The Importance of Cooling Towers in Mechanical Construction

While not every project requires a cooling tower, they are often incorporated into designs where large-scale cooling is necessary to maintain optimal system performance. In such cases, these mechanical equipment help reduce energy consumption and enhance overall HVAC efficiency. These towers are engineered to remove excess heat generated by chillers, condensers, and other industrial equipment by utilizing water evaporation and heat exchange processes. They are particularly beneficial in projects where air-cooled systems alone would be insufficient or inefficient due to scale and climate conditions.

The design and type of cooling tower used depend on various factors, including building size, cooling load, climate, and energy efficiency goals. Proper placement and integration in a mechanical system can significantly impact operational efficiency, maintenance requirements, and longevity.

For businesses and general contractors involved in new construction or planning upgrades and maintenance of these mechanical devices, selecting the right system and working with experienced mechanical specialists is crucial. Proper integration of these mechanical equipment can improve long-term efficiency, ensure compliance with building regulations, and optimize overall mechanical system performance. Additionally, implementing water treatment programs and routine inspections is essential to maintain cooling tower efficiency, prevent scaling and biological growth, and extend the system’s lifespan.

Kilgore Industries was founded as a mechanical contractor in Houston, TX, with a commitment to delivering high-quality HVAC, mechanical, and industrial solutions for commercial and large-scale construction projects. Over the years, Kilgore expanded its expertise beyond mechanical contracting to include electrical and plumbing construction services, positioning itself as a full-service MEP (Mechanical, Electrical, and Plumbing) contractor for the entire state of Texas.